Technical Workshop Guide: John Deere 18-Speed PST Repair Technical Manual

Need to fix your equipment? This professional service guide is the official resource for expert mechanics. It includes specific electrical wiring diagrams and hydraulic troubleshooting steps tailored for this specific model.

This technical documentation for the Brand series provides OEM specifications, torque settings, and assembly instructions.

- Official Brand Category: VIEW ALL BRAND MANUALS

- Model Focus: High-resolution data for John Deere 18-Speed PST Repair Technical Manual.

What's inside this Brand manual?

- Engine Overhaul

- Transmission Specs

- Hydraulic Schematics

- Electrical Diagrams

- Diagnostic Codes

- Maintenance Intervals

John Deere 18-Speed PST Repair Technical Manual

(CTM168)

Table of Contents:

General Information

- Transmission identification and serial number plate

- Safety guidelines for fluid handling and high-pressure systems

- Recommended lubricants and oil storage best practices

- Transmission maintenance intervals and storage recommendations

Transmission Repair and Adjustments

- Transmission mounting and removal procedures

- Input and output shaft seal replacements

- Yoke removal and installation

- Transmission bearing retainer O-ring servicing

Electrical System

- Transmission wiring harness removal and installation

- Proportional solenoid valve diagnostics and servicing

- Speed and temperature sensor replacements

- Oil pressure switch troubleshooting

Hydraulic System

- Oil filter and suction screen maintenance

- Oil pump removal, disassembly, and reinstallation

- Main regulator valve and bypass valve servicing

- Oil level sight glass replacement (for wheel tractors)

Geartrain and Clutch Shafts

- Clutch shaft assembly disassembly and reassembly

- Exploded views of input and output shaft components

- Rear housing with internal park brake removal

- Clutch bearing adjustments and installation

Theory of Operation

- Gear selection and clutch actuation principles

- Directional and speed clutch operation

- Hydraulic system flow diagrams and pressure regulation

- Proportional solenoid valve operation

Tools and Specifications

- Essential and dealer-fabricated tools for transmission servicing

- Torque values for bolts, screws, and hydraulic fittings

- Metric and unified inch specifications for fasteners.

John Deere 18-Speed PST Repair Technical Manual

Table of Content

Foreword

Notice to the Dealer

01 – General Information

000 – Safety

Recognize Safety Information

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Handle Chemical Products Safely

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Avoid Harmful Asbestos Dust

Avoid Heating Near Pressurized Fluid Lines

Remove Paint Before Welding or Heating

Use Proper Tools

Construct Dealer-Made Tools Safely

Dispose of Waste Properly

Live With Safety

10 – General Information

Identification Plate

General Repair Procedures

Sealants and Adhesives Cross-Reference Chart

Sealing Instructions

Cold Weather Operation

Oil Temperature Warning Signal

Recommended Lubricants

Lubricant Storage

Mixing of Lubricants

Oil Analysis

Alternative and Synthetic Lubricants

Check and Service Transmission Regularly

Intervals For Changing Transmission Oil Filters

Fill The Transmission With Oil (Wheel Tractors Only)

Check Oil Lines and Fittings

Hydraulic Connections

Transmission Storage

Transmission Removal From Storage

Towing The Vehicle

02 – Repair and Adjustments

15 – Transmission

Repair Stand Safety Precautions

Engine Repair Stand

Install Adapter to Engine Rollover Stand

Install Transmission Mounting Bracket

Install Transmission to Rollover Stand Bracket

Remove Transmission from Rollover Stand Bracket

Remove and Install Yoke

Replace Input and Output Shaft Seals (In Tractor)

Replace Bearing Retainer O-Ring Seals

20 – Electrical

Remove and Install Wiring Harness Bracket

Replacing the Transmission Wiring Harness

Front Housing Sensors and Ports

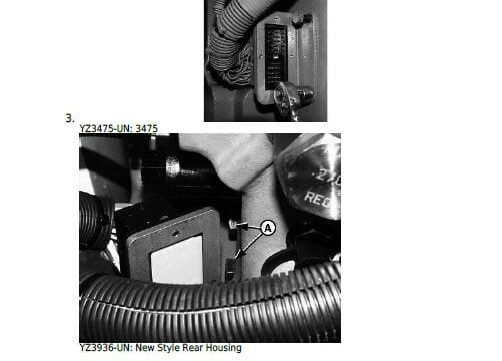

Rear Housing Sensors and Ports

Proportional Solenoid Identification – Left Side

Proportional Solenoid Identification – Right Side

Install Proportional Solenoid Valve

Remove and Install Input and Cylinder Speed

Magnetic Pickup Sensors

Remove and Install Fifth Stage Magnetic Pickup Sensor (Speed)

Remove and Install Output Magnetic Pickup Sensors

Remove and Install Oil Filter Head Pressure Switch

Remove and Install System Pressure Sensor

Remove and Install Temperature Sensor

25 – Hydraulics

System Components

Remove and Install Suction Screen

Remove and Install Oil Filter

Remove and Install Oil Filter Inlet Tube

Oil Filter Head

Remove Oil Filter Switch

Disassemble and Assemble Filter By-Pass Valve

Remove, Repair and Install Oil Filter Head

Remove, Repair and Install Main Regulator Valve

Remove and Install Lube Relief Bypass Valve

Remove and Install Cooler Relief Bypass Valve

Remove Oil Level Sight Glass (Wheel Tractors Only)

Repair Oil Level Sight Glass (Wheel Tractors Only)

Install Oil Level Sight Glass (Wheel Tractors Only)

30 – Pump Drive

Remove and Install Oil Line to Input Bearing

Remove and Install Transmission Vent Fitting

Remove Pump Drive Cover

Disassemble and Assemble Pump Drive Cover

Install Pump Drive Cover

Remove, Repair and Install Oil Pump Gear Assembly

Remove Transmission Oil Pump

Disassemble, Inspect and Assemble Transmission Oil Pump

Install Transmission Oil Pump

Remove and Install Pump Drive Input Gear

35 – Housings, Geartrain and Clutch Shafts

Remove Rear Housing With Internal Park Brake

Disassemble Rear Housing

Remove Clutch Shaft Sealing Ring Sleeve Old Style

Rear Housing Design

Install Bore Sleeves Old Style Rear Housing Design

Remove Clutch Assemblies

Exploded View— Output Shaft Without Internal Park Brake

Exploded View— Output Shaft With Internal Park Brake

Remove and Install Axle Pump Stand Pipe

Remove, Disassemble and Assemble Output Shaft Assembly

Remove Suction Tube Old Style Rear Housing

Remove Suction Tube

Install Output Shaft Assembly

Install Suction Tube Old Style Rear Housing

Install Suction Tube

Remove and Install Output Shaft Oil Dam

Exploded View—First Stage Shaft Assembly (Input Shaft)

Exploded View—Second Stage Clutch Shaft Assembly

Cross-Sectional View—Second Stage Clutch Shaft Assembly

9620 Series Exploded View—Second Stage Clutch Shaft Assembly

9620 Series Cross-Sectional View—Second Stage

Clutch Shaft Assembly

Exploded View—Third Stage Clutch Shaft Assembly

Cross-Sectional View—Third Stage Clutch Shaft Assembly

9620 Series Exploded View—Third Stage Clutch Shaft Assembly

9620 Series Cross-Sectional View—Third Stage Clutch Shaft Assembly

Exploded View—Fourth Stage Clutch Shaft Assembly

Cross-Sectional View—Fourth Stage Clutch Shaft Assembly

9620 Series Exploded View—Fourth Stage Clutch Shaft Assembly

9620 Series Cross-Sectional View—Fourth Stage Clutch Shaft Assembly

Exploded View—Fifth Stage Clutch Shaft Assembly

Cross-Sectional View—Fifth Stage Clutch Shaft Assembly

9620 Series Exploded View—Fifth Stage Clutch Shaft Assembly

9620 Series Cross-Sectional View—Fifth Stage Clutch Shaft Assembly

Exploded View—Sixth Stage Clutch Shaft Assembly

Cross-Sectional View—Sixth Stage Clutch Shaft Assembly

9620 Series Exploded View—Sixth Stage Clutch Shaft Assembly

9620 Series Cross-Sectional View—Sixth Stage Clutch Shaft Assembly

Exploded View—Seventh Stage Clutch Shaft Assembly

Cross-Sectional View—Seventh Stage Clutch Shaft Assembly

9620 Series Exploded View—Seventh Stage Clutch Shaft Assembly

9620 Series Cross-Sectional View—Seventh Stage Clutch Shaft Assembly

Disassembly and Assembly of Clutch Stage Shaft Assemblies

Disassemble and Assemble Second Stage Shaft Assembly

Disassemble and Assemble Fifth Stage Shaft Assembly

Disassemble and Assemble Seventh Stage Clutch Shaft Assembly

Disassemble and Assemble Sixth Stage Clutch Shaft Assembly Assembly

Disassemble and Assemble Third Stage Shaft Assembly

Install Clutch Assemblies

Install Rear Housing

Bearing Adjustment of Output Shaft Rear Housing

Internal Park Brake Assembly

Bearing Adjustments to Clutch Stage Shafts

Install Clutch Rotation Tools

Bearing Adjustment Of Fifth and Sixth Clutch

Stage Shaft Assemblies

Bearing Adjustment of Second, Third, Fourth and

Seventh Clutch Stage Shaft Assemblies

Bearing Adjustment of Output Shaft Front Housing

Bearing Adjustment of Input Shaft

03 – Theory of Operation

20 – Theory of Operation

Transmission Operation

Gear Selection

Clutch Actuation

Gear Train Operation

Directional and Speed Clutch Operation

Range Clutch Operation

Internal Park Brake Operation

Transmission Hydraulic Diagram

Transmission Hydraulic Diagram – Internal Park

Brake Model

Transmission Pump Operation

Oil Filter Head

Main Regulator Valve

Main Regulator Valve Operation

Proportional Solenoid Valve Operation

Powershift Control Unit

05 – Tools and Other Materials

175 – Special Tools

Essential Tools For JDG9x20PST

Essential Tools for JDG9x20PSTWB

Other Material

195 – Dealer Fabricated Tools

DFRW146 Relief Valve Removal Tool

Guide Pins For Front And Rear Housing

Guide Pin for Shims, Caps and Pump Housings

06 – Specifications

205 – Torque Value

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Fittings, O-ring and Hose