Technical Workshop Guide: John Deere 310J and 310SJ Backhoe Loader Operators Manual

Need to fix your equipment? This professional service guide is the official resource for expert mechanics. It includes specific electrical wiring diagrams and hydraulic troubleshooting steps tailored for this specific model.

This technical documentation for the Brand series provides OEM specifications, torque settings, and assembly instructions.

- Official Brand Category: VIEW ALL BRAND MANUALS

- Model Focus: High-resolution data for John Deere 310J and 310SJ Backhoe Loader Operators Manual.

What's inside this Brand manual?

- Engine Overhaul

- Transmission Specs

- Hydraulic Schematics

- Electrical Diagrams

- Diagnostic Codes

- Maintenance Intervals

John Deere 310J and 310SJ Backhoe Loader Operators Manual

(OMT210365 Issue B3)

John Deere 310J and 310SJ Backhoe Loader Operators Manual

The John Deere 310J and 310SJ Backhoe Loader Operators Manual provides essential guidance for safe operation, maintenance, and performance optimization of these powerful construction machines. Users searching for this manual typically want clear instructions on machine controls, daily inspections, lubrication points, and troubleshooting steps. The manual helps operators understand key functions such as boom, dipper, and loader operations while also providing safety protocols to prevent equipment damage. Having the correct operators manual ensures your 310J or 310SJ runs efficiently and remains compliant with recommended maintenance schedules.

What kind of hydraulic fluid does a 310J and 310SJ Backhoe Loader take?

The John Deere 310J and 310SJ require John Deere Hy-Gard hydraulic/transmission fluid, a high-performance oil designed for extreme pressure conditions. This is the recommended fluid for optimal hydraulic response, reduced wear, and long-term component protection. Hy-Gard meets both JDM J20C (standard viscosity) and JDM J20D (low-viscosity) specifications. Most operators search for this information when performing routine maintenance or diagnosing weak hydraulics, ensuring they use the correct oil for smooth loader and backhoe performance.

Model Covers:

310J and 310SJ Backhoe Loaders

Engines 4045DT060, 4045HT054 and 4045TT094

File Format: PDF

Size: 8.55 MB

No. of pages: 244

Language: English

Table of Contents Overview:

Safety Guidelines and Precautions

- Recognizing safety information and following procedures

- Protective gear requirements and workplace safety

- Emergency preparedness and fire prevention

Operating Instructions

- Daily machine inspection and startup checklist

- Operating boom locks, swing locks, and stabilizers

- Hydraulic and auxiliary functions control

Maintenance and Troubleshooting

- Regular service intervals and fluid checks

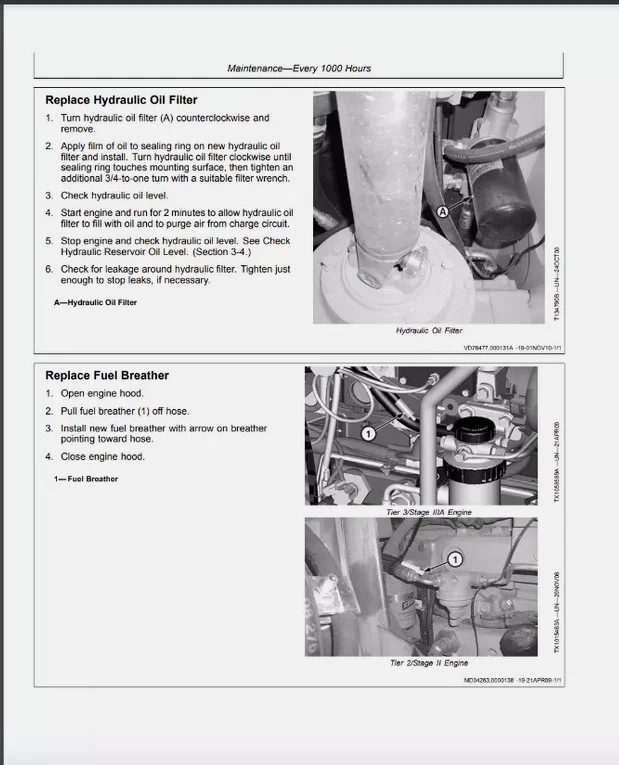

- Lubrication and hydraulic system maintenance

- Engine diagnostics and troubleshooting procedures