New Holland Service & Repair Manual: New Holland LW110.B Troubleshooting: Engine, Hydraulic and Electric

In need of a New Holland Service Manual or Repair Manual for your construction equipment? This guide offers high-resolution hydraulic flow schematics and fault code diagnostics essential for professional maintenance and transmission troubleshooting.

Are you dealing with a transmission calibration error, hydraulic pressure drop, or engine fault on your equipment? This official New Holland LW110.B Troubleshooting: Engine, Hydraulic and Electric is the definitive shop tool for New Holland mechanics. It delivers step-by-step service instructions, precise assembly clearances, and genuine factory specifications to resolve complex issues and ensure Tier 4B / Final engine compliance.- Official Brand Category: NEW HOLLAND SERVICE MANUALS

- Model Coverage: Full technical shop data for the New Holland LW110.B Troubleshooting: Engine, Hydraulic and Electric series. This manual covers C-Series, L-Series, and T-Series updates, including hydraulic flow settings, CAN-bus electrical data, and PTO/drivetrain specs.

- Document Specs: Factory Workshop Manual, Searchable PDF, High-Resolution Electrical & Hydraulic Schematics.

Core Workshop Content:

- Operational Performance Tests: Diagnostic Testing

- Transmission: Powershift & CVT Repair

- Hydraulic Systems: Open/Closed Center Schematics

- Electrical: Controller & Harness Layouts

- Engine Service: Valve Adjustments & Torque

- Axles & Brakes: Final Drive Overhaul

- Troubleshooting: Fault Code Diagnostics

- Safety: New Holland Service Standards

Don't risk machine reliability with unofficial data. Use the correct New Holland service data. Explore our New Holland LW110.B department for more technical resources.

New Holland LW110.B Troubleshooting: Engine, Hydraulic & Electric

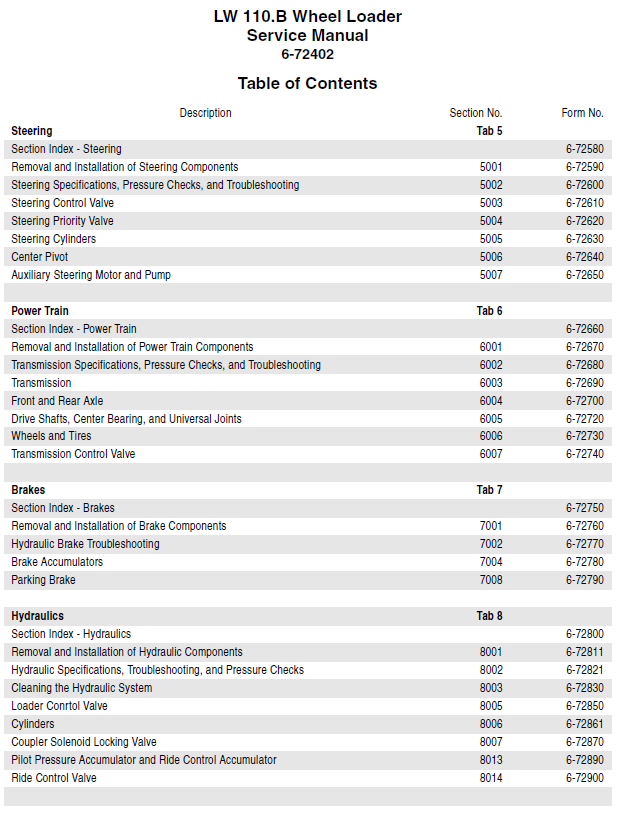

New Holland LW110.B Wheel Loader Service Manual

The New Holland LW110.B wheel loader is a workhorse known for its reliability, but like any heavy machinery, it is susceptible to wear and tear. When your loader faces downtime, identifying the root cause quickly is essential to maintaining your project timeline. This guide explores the most common engine, hydraulic, and electrical issues associated with the LW110.B. Heavy Equipment, Troubleshooting.

New Holland LW110.B Engine & Start Failures

Starting issues are the most frequent cause of unplanned downtime. For the LW110.B, these usually stem from fuel delivery or basic electrical engagement.

Engine Won’t Start or Starts Intermittently

If your New Holland engine turns over but fails to ignite, start by checking the fuel system. Clogged fuel filters or air in the lines are common culprits. For intermittent starts, inspect the ignition switch and the fuel shut-off solenoid; if the solenoid is failing, it may not consistently allow fuel to reach the injectors.

Starter Click but No Crank

A “clicking” sound upon turning the key indicates that the starter solenoid is engaging, but the motor isn’t spinning. This is often caused by:

- Poor Grounding: Heavy vibration can loosen the ground straps on the LW110.B frame.

- Terminal Corrosion: Ensure battery posts are free of oxidation.

- Voltage Drop: Test the battery under load; a battery may show 12V but lack the cold-cranking amps (CCA) required for a diesel engine.

Battery Drain and Alternator Faults

If the battery dies after sitting for a few hours, you likely have a parasitic drain. Check for aftermarket lights or radios left on. If the battery dies while the machine is running, the alternator is likely failing to provide a charge, often signaled by a battery icon on the dashboard.

Hydraulic Performance Concerns

The LW110.B relies on a high-pressure hydraulic system for its lifting and bucket functions. Performance drops here directly impact your cycle times.

New Holland LW110.B Troubleshooting: Engine, Hydraulic & Electric

Hydraulic Slow Lift and Pressure Loss

A “slow lift” usually points to a lack of flow. Check the hydraulic oil level and the condition of the suction strainer. If the oil appears milky, water has contaminated the system. If levels are fine, the main hydraulic pump may be reaching the end of its service life or the relief valve may be stuck in the open position.

Jerky Loader Response

If the loader arm or bucket moves in a “jumpy” fashion, air has likely entered the system. This can occur after a hose replacement if the system wasn’t properly bled. Alternatively, worn pins and bushings or a sticking control valve spool can cause inconsistent movement.

Hydraulic Oil Overheating

Overheating is often caused by a blocked hydraulic oil cooler or a bypass valve failure. High temperatures thin the oil, leading to a noticeable loss in breakout force and potential damage to internal seals.

Electrical & Sensor Troubleshooting

Modern New Holland loaders utilize an Electronic Control Unit (ECU) to monitor vital signs. Understanding these signals is key to advanced diagnostics.

Warning Lights and Dashboard Fault Codes

The LW110.B dashboard displays specific fault codes (often SPN or FMI codes) when a sensor detects a value outside the normal range. Always reference the specific New Holland fault code list to identify if the issue is high coolant temperature, low oil pressure, or a transmission glitch.

ECU and Sensor Communication Faults

“Communication error” codes often result from damaged wiring harnesses. In the harsh environment of a construction site, wires can be pinched or frayed. Ensure all sensor plugs—especially those on the engine and transmission—are seated firmly and free of moisture.