Technical Workshop Guide: Daewoo Doosan Mega 500-v Service Catalogue Manual

Need to fix your equipment? This professional service guide is the official resource for expert mechanics. It includes specific electrical wiring diagrams and hydraulic troubleshooting steps tailored for this specific model.

This technical documentation for the Daewoo Doosan series provides OEM specifications, torque settings, and assembly instructions.

- Official Brand Category: VIEW ALL DAEWOO DOOSAN MANUALS

- Model Focus: High-resolution data for Daewoo Doosan Mega 500-v Service Catalogue Manual.

What's inside this Daewoo Doosan manual?

- Engine Overhaul

- Transmission Specs

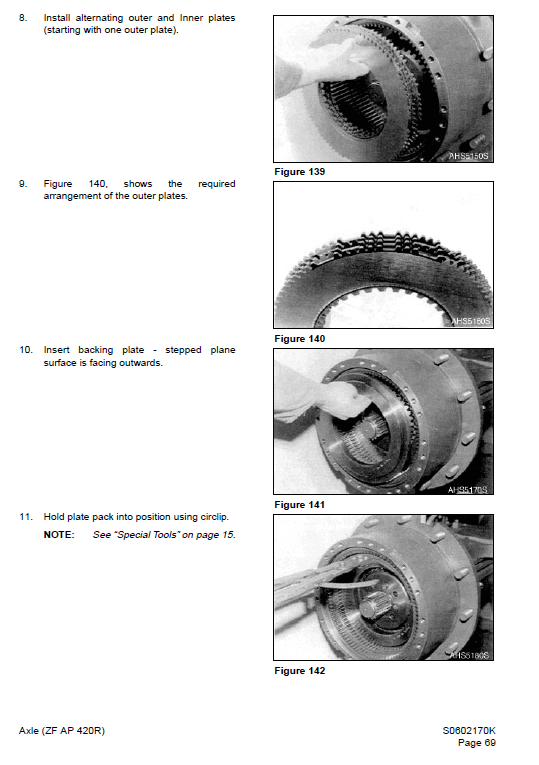

- Hydraulic Schematics

- Electrical Diagrams

- Diagnostic Codes

- Maintenance Intervals

Daewoo Doosan Mega 500-v Wheeled Loader Service Parts Catalogue Manual

Maintenance:

A liquid crystal display conveys information to the operator relative to the ZF transmission.

At the same time, it reports the nature of a problem (if one exists). When servicing the loader,

a specialised apparatus can be used to adjust the clutch disks to compensate for their wear.

Additionally, by connecting a lap top computer, a complete transmission diagnostic can be performed.

Table of Contents

- Safety

Wheel Loader Safety…S0103010K

Specifications

Specifications for Mega 500-V S0203070K

General Maintenance

General Maintenance Procedures……S0302000

Standard Torques…….S0309000

Upper Structure

Counterweight. S0403040K

Fuel Transfer Pump….S0405500

Hydraulic Oil Tank … S0406040K

Lower Structure and Chassis

Center Joint (Articulation Joint)…….. S0502020K

Engine and Drive Train

Axle (ZF AP 420R)… S0602170K

Air-Conditioner S0605050K

Transmission and Torque Converter (ZF 4WG-310)…….. S0607080K

Transmission Error Codes (ZF) ……. S0607900C

Hydraulics

Accumulator…….S0703000

Cylinders…S0705010

Main Pump (Denison T6DMY Series)……. S0708460K

Steering and Brake Pump (Denison T67DB Series) S0708470K

Brake Pedal Valve … S0709240K

Main Control Valve (Toshiba) . S0709455K

Pilot Control Valve … S0709476K

Flow Amplifier (Danfoss)… S0709665K

Power Steering Unit. S0709730K

Restriction Valve…… S0709750K

Hydraulic Schematic (Mega 500-V). S0793060K

Electrical System

Electrical System S0802190K

Electrical Schematic (Mega 500-V) . S0893060K

Attachments

Daewoo Doosan Mega 500-v Wheeled Loader Catalogue Manual

Increased Axle durability

The brake discs have been repositioned to the rear part of the reduction gear where the rotation speed is lower. As a result, the discs are exposed to lower RPMs, heat generation is reduced and the life span of the discs is greatly extended. An automatic disc clearance regulator has been integrated into the design and the disc clearance is maintained at the optimum level at all times as the discs wear out. This prevents any lag in brake response. Another convenient feature is that brake disc wear can easily be measured without disassembling the hub.

The brake piping has been redesigned into the axle housing and is protected from damage from external shock as the machine drives over rough terrain.